Zfx™ GenTek™

Genuine Restorations & Open Digital Workflows

Premium implants deserve premium prosthetic components. For long-term clinical success, it is essential that the interface between the implant and abutment are designed to work together. This is the only way to ensure a robust and stable interface that delivers the long-term aesthetic and physical integrity that patients demand.

The GenTek™ Restorative Components are the solution for anyone who uses genuine Zimmer Biomet Dental implants. As part of an open digital workflow, the genuine connection Ti-Bases and Premilled Abutment Blanks ensure the highest product quality and a precise fit through the integration of proven Zimmer Biomet Dental technologies. GenTek™ Restorative Components are available for Zimmer Biomet Dental implant systems Certain®, External Hex, TSV™ / Trabecular Metal™ and Eztetic®.

Coming soon in 2019:

- Ti-Bases and ancillary components for Certain®, External Hex® and Eztetic® connections

- Ti-Bases for full-arch restorations

- Pre-milled Abutment Blanks for all 4 connections

All content herein is protected by copyright, trademarks or other intellectual property rights, as applicable, owned by or licensed to Zimmer Biomet or its affiliates unless otherwise indicated. ©2019 Zimmer Biomet.

CEREC and Sirona are trademarks of Dentsply Sirona or its affiliates.

The power of genuine connections

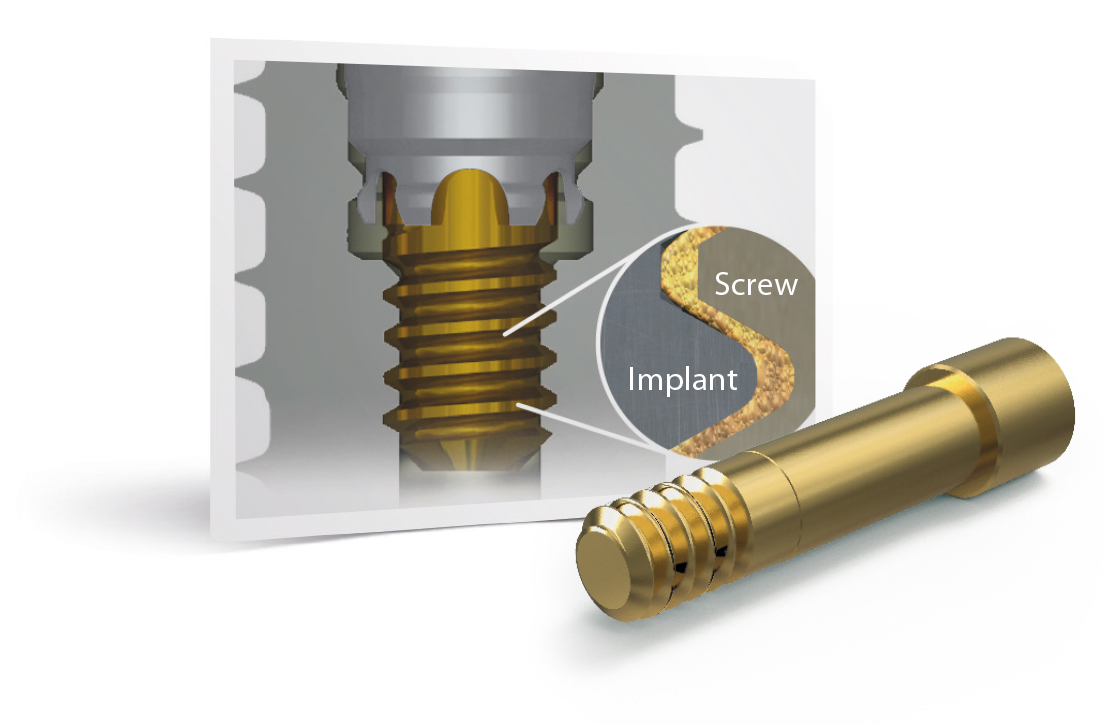

Maintaining the integrity of the interface between the implant and abutment is imperative for implant system performance and mitigating potential clinical implications that may occur due to an inferior seal.

Imprecise fit of components may result in bacterial colonization of the internal aspect of the implant, (not a period) which may lead to soft tissue inflammation and to loss of implant integration.4 Component misfit may also lead to screw joint failure, screw loosening, and compromised long-term prosthetic stability.4

Zimmer Biomet Dental’s Friction-Fit Technology for TSV™, Trabecular Metal™, and Eztetic™ Implant Systems

Our unique friction-fit abutments create a virtual cold weld with the implant when fully seated and tightened to the recommended torque of 30 Ncm.5 This connection virtually eliminates rotational micro-movement, tipping and vibration-related micromovement of the abutment, which otherwise result in screw loosening and prosthetic instability.2

Our friction-fit connection:

- Minimizes costly repairs and replacement

- Minimizes repeat visits to the dentist

- Shields both the abutment screw and crestal bone from concentrated occlusal forces6,7,8creating favorable conditions for crestal bone-level maintenance6,7

Image: SEM at 150X magnification displays the mechanical interlock in the hexagonal engagement area between the flats of the implant and abutment.

Zimmer Biomet Dental’s SureSeal™ Technology for Certain® and External Hex Implant Systems

- SureSeal™ Technology provides superior seal integrity at the interface between the implant and abutment. This is achieved with the combination of the proprietary Gold-Tite® Screw, Certain®Internal and External Hex connection, and precision manufacturing.

- The Proprietary Gold-Tite® Screw surface technology allows the screw to engage further, increasing the clamping force by up to 113 %, compared to standard screws9, thereby maximizing the abutment stability10. A stable and tight implant abutment interface minimizes abutment micromotion and reduces potential microleakage, that can otherwise lead to inflammation associated with bone and tissue loss.11

1. Zitzmann NU, Berglundh T. Definition and prevalence of peri-implant diseases. J Clin Perio. 2008;35:286–291. 2. Lazzara RJ†, Porter SS†. Platform Switching: A new concept in implant dentistry for controlling post restorative crestal bone levels. Int J Periodontics Restorative Dent. 2006;26:9-17. 3. Fransson C, Lekholm U, Jemt T, Berglundh T. Prevalence of subjects with progressive bone loss at implants. Clinical Oral Implants Research. 2005;16:440–446. 4. Kofron et. al (2017, September). Quantitative Contribution of Friction Fit Connection to Connection Strength and Stability. Poster presented at the annual American Academy of Periodontology, Boston, MA 5. Binon PP: The evolution and evaluation of two interference-fit implant interfaces. Postgraduate Dent 1996;3:3-13. 6. Mihalko WM, May TC, Kay JF, Krause WP. Finite element analysis of interface geometry effects on the crestal bone surrounding a dental implant. Implant Dent. 1992;1:212-217. 7. Chun HJ, Shin HS, Han CH, Lee SH. Influence of implant abutment type on stress distribution in bone under various loading conditions using finite element analysis. Int J Oral Maxillofac Implants. 2006;21:105-202. 8. Binon PP. The evolution and evaluation of two interference-fit implant interfaces. Postgraduate Dent. 1996;3:3-13. 9. Suttin Z††, Towse R††. Effect of abutment screw design on implant system seal performance. Presented at the European Association for Osseointegration, 20th Annual Scientific Meeting; October 2012; Copenhagen, Denmark. http://biomet3i.com/Pdf/Posters/P-450_Effect_of_Screw_Design_on_Implant…. 10. Byrne D, Jacobs S, O’Connell B, Houston F, Claffey N. Preloads generated with repeated tightening in three types of screws used in dental implant assemblies. J. Prosthodont. 2006 May–Jun;15(3):164-171. 11. Lazzara R.†† Dental implant system design and the potential impact on long-term aesthetics: A review of the T3 Tapered Implant. ART1193EU Biomet 3i White Paper. Biomet 3i, 2012, Palm Beach Gardens, Florida, USA. https://www.zimmerbiometdental.com/dental/ART1193EU_Implant_White_Paper…